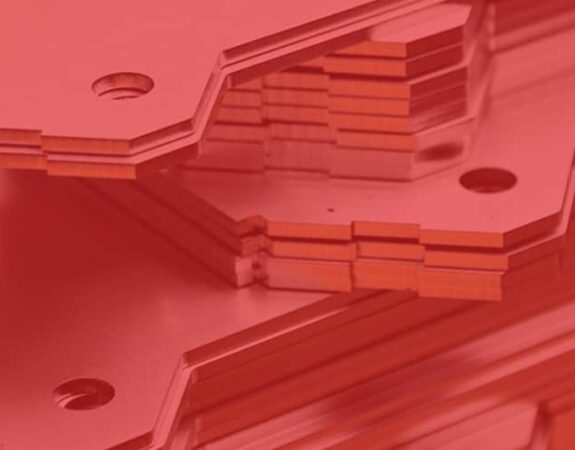

Specialists in laser cutting, marking and engraving with a focus on ceramics. Over 35 years’ experience manufacturing and supplying precision laser cut ceramic substrates, and other materials, to a wide range of industries

Over 50 years of precision excellence

With a focus on quality and customer service, we offer a complete manufacturing solution. We are precision engineering specialists, offering precision machining, sheet metal fabrication and assembly solutions to all industries.

Engineering Excellence

From prototype builds to volume production runs, we are here to support you.

Customer Focus Dedicated account management

Quality service and manufacture

Prototypes through to volume production

Supporting any industry

Shearline Precision Engineering offers a quality service and delivers quality parts: it is what we’re renowned for.

We’re big enough to handle contracts of any size but small enough to still offer a personal level of service.

“Congratulations to Shearline, one of our near neighbours in the Cambridgeshire area, on its 50th Anniversary! We are not far behind you at Domino Printing Sciences and for 30 of those years you have been ever-present, supplying critical components to our inkjet business through all the challenges the world has thrown at us and making a significant contribution to our sustained business growth. A real asset to British manufacturing.”

Carl Haycock, UK Operations Director at Domino Printing

Over

years

Experience, Founded in 1973

Over

sq2

Square feet of production space

Working with over

Different industry sectors