EN 9100:2018 Accredited Manufacture

We operate a QMS which complies to the requirements of EN 9100:2018 – we’ve proudly held this certification for over 15 years.

We are committed to our customers’ quality requirements and offer a wide range of supporting quality documentation, including:

Please state your quality requirements at point of enquiry.

Having held the AS9100 accreditation since 2007, we are a trusted supplier to the aerospace industry.

We are proud to work with a range of clients in the aerospace industry – supporting businesses at all levels of the supply chain.

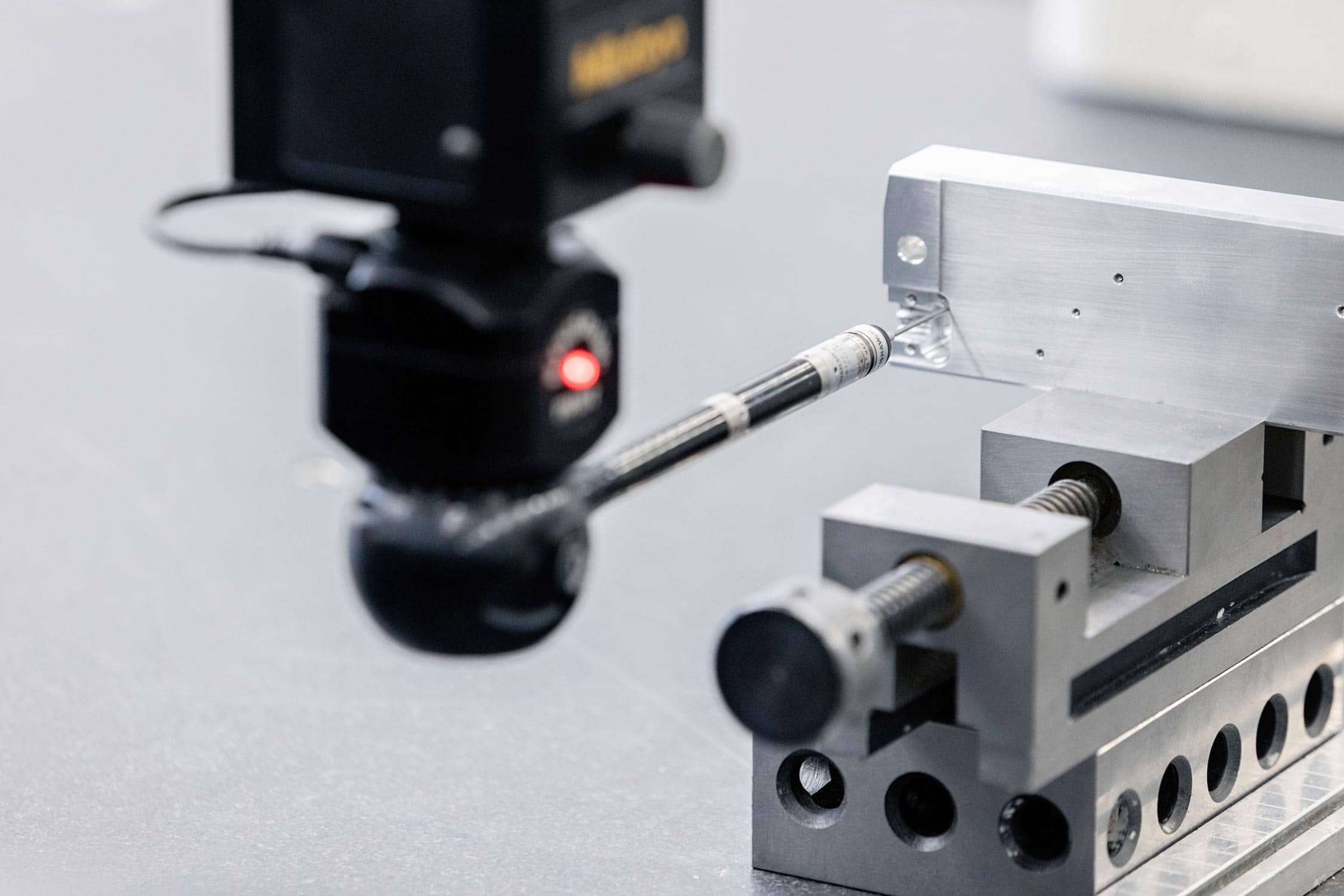

Our dedicated inspection facility is equipped with a number of sophisticated measurement tools, including two fully automated Mitutoyo Coordinate Measuring Machines (CMMs). One of which has a table size of 1000mm x 2000mm x 1000mm and is devoted to the larger components that we manufacture.

A shadowgraph and surface roughness tester provide us with an additional method to check components.

Our experienced Quality team also have access to a wide range of conventional measuring equipment, all of which is calibrated on a regular basis.

Our temperature-controlled inspection facility is cooled to the industry standard, providing an environment for parts to stabilise before being measured.

All operations across the entire workflow process are controlled by our industry specific ERP system.